The roots of LaMeRoc ground in the world of Research and Technological Development (RTD). To face the multiple challenges that we have addressed so far, we have mastered in certain skills that involve the conceptualization, design, manufacture, testing and application of equipment for special tests.

Some of them meet the specific needs of relevant companies, while others convey our own initiatives and are aimed at deepening into the knowledge of techniques, processes and materials.

At present, the RTD activities of LaMeRoc mainstream two major groups: a) Design and fabrication of equipment; b) Advanced application of additive manufacturing techniques.

Design, Manufacturing and Experimental Developments

LaMeRoc has a small workshop to carry out small mechanical and electronic work. For large projects or large-size equipment, we have the human and material support of CITEEC as well as a network of companies of proven soundness.

Programmable high-pressure, high-precision hydraulic pumps; Floating piston cylinders; Specialized equipment (He pycnometer, thermal conductivity, etc.); Devices for high-temperature geomechanical testing; Core holders; Systems integration; Etc.

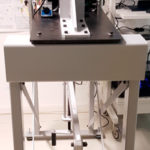

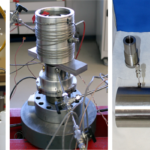

- Large true triaxial system

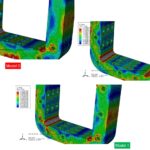

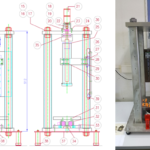

- Load frame finite element analysis

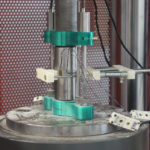

- Mode I fracture toughness frame

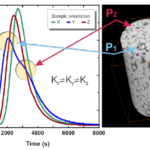

- Fracture toughness testing

- Multipurpose testing frame

- High P syringe pump

- High T shear testing system

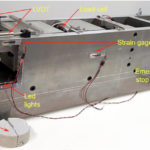

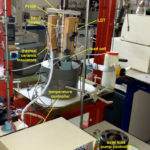

- Sanding cell

- High P feedthru

- Small size load frame

- High T consolidometer

- Breakthrough curves in tracer test

- Instrumented core holders

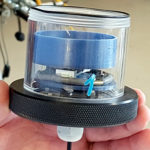

- Fluid exchange vessel

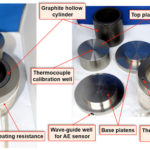

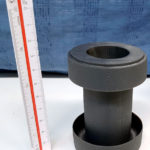

- High T consolidometer parts

- Fluid exchange vessel

- High T consolidometer

- High P syringe

Additive Manufacturing

While the core activity of LaMeRoc focus on rock mechanics we also conduct active research on new technological applications of polimer-based additive manufacturing.

Flexible materials; High strength materials; Enhanced properties materials (e.g. piezoresistive, conductive); Triaxial sleeves; Instrumented sleeves; Diverse instrumentation; Etc.

- High P sleeve

- Printed feed-through

- Axial and radial strain measurements

- Axial and radial strain measurements

- Sanding cell

- Sanding test sleeve

- Sanding test accesories

- Miniature printed scale

- Instrumented printed sleeve

- Lateral extensometer